The Basics of Wastewater Treatment

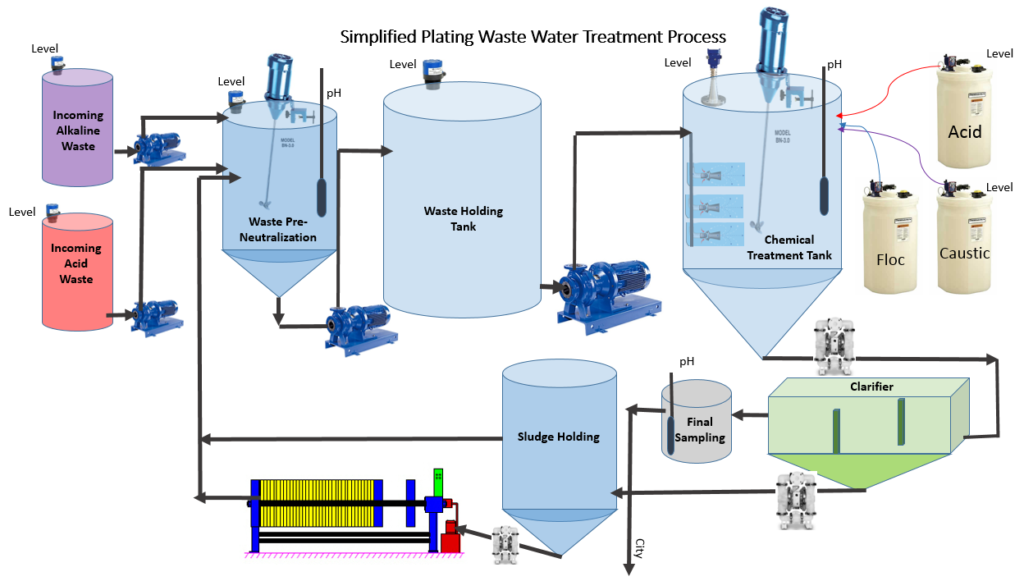

Wastewater treatment of plating and metal finishing process is a complicated process with multiple steps. This article briefly discusses some of the main points and products involved.

Plating wastewater has several issues to overcome. You have solutions that can include acids, caustics, solvents, water, and usually metal particulate. Each of these in their own right can have complications in treating these types of fluid streams. The other complication is the cost-effective treatment of the wastewater stream while still meeting local City requirements.

One of the ways to cut down on costs is to use the spent and dirty acid and caustic based solutions to help pre-treat/neutralize each other. That way, you are using less chemical than you would if you tried to balance the pH of both waste streams individually.

Product Selection is Key

Selecting products that can both handle the varies chemistries and work effectively is a balancing act. You need to select products that are both easy to maintain and cost-effective. One of the key decisions is to allow for enough retention time in the treatment tanks. This takes the form of first selecting large enough storage tanks (that can also handle heavy (specific gravity) solutions). Then there must be thorough mixing to ensure the waste streams have adequate time to react and neutralize each other. Proper mixing and retention time will help ensure that you do not waste chemical by “over-shooting” the desired pH set point.

Selecting the right level control sensors and pH probes is also important. Both must be able to handle the rough environment and temperature swings that can occur due to exothermic reactions common in neutralization systems.

Finally, pump selection is critical. Many pumps seem to work, but don’t last due to the chemistries and or particulate present in the fluid. Wetted materials and seal selection is important along with proper flow rate and performance sizing to ensure long pump life. This is true for chemical injection pumps, centrifugal or AODD transfer pumps present in the system.

RHFS’ TechTeam to the Rescue!

Does this sound familiar to you? If you’d like some assistance optimizing your wastewater treatment process, please contact your local RHFS Office for more details. You can also contact our Tech Services Team directly at 877-741-7473 or via email at techsupport@rhfs.com