Iwaki Mag-Drive Pumps: Built to Last

Long-Term Performance Champs

The old expression that a chain is only as strong as its weakest link can be easily be applied to non-metallic magnetic-drive chemical pumps also. Most components in the pump end are strong enough to hold up to harsh chemicals and typical wear. However, when there is an upset in the system the weakest link of the chain is exposed.

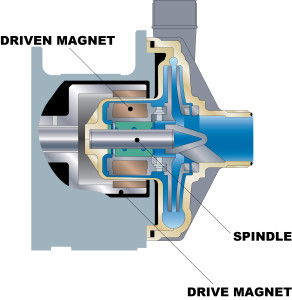

In a Mag-Drive pump the spindle is the highest load point and the first component to fail in pump upset conditions.

In the case of mag-drive chemical pumps it is the pump shaft or spindle. Magnetic drive pumps are unique in that there is no direct coupling from the motor to the impeller. A drive magnet attached to the motor is magnetically coupled to a driven magnet within the pump end. As the motor spins the magnetic attraction spins the driven magnet which is attached to the impeller. This inner magnet and impeller need to be supported by the spindle. Being a chemical pump, utilizing a strong material such as metal is not recommended so a ceramic spindle is typically used. Ceramics are fragile and can fracture when stressed. Upset conditions lead to these stresses and can cause spindle failure.

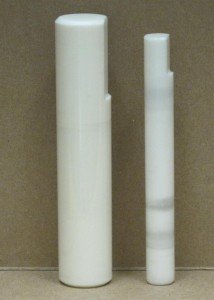

Iwaki pumps feature a spindle that is three times the industry standard to help protect against upset conditions. Instances of cavitation (too much flow), dead heading (no flow) and constant starting and stopping put stress on the pump’s spindle. Iwaki’s oversized spindle will survive these conditions with no damage to the pump.

Iwaki Mag-Drive pumps feature a rugged spindle that is three time the size of their leading competitor for superior long-term performance.

Iwaki’s MX series of pumps is available in both Polypropylene and ETFE Teflon for a variety of chemical applications. Manufactured in Massachusetts and stocked nationally by Ryan Herco Flow Solutions, the Iwaki MX series of pumps is your best choice for chemical applications.