The Importance of Ultra High-Purity in the Food and Beverage Industry

The CDC estimates that each year 48 million Americans eat something that makes them ill. Thus cleanliness is of a paramount concern to the food & beverage industry as any contamination can be very expensive. To prevent this, food and beverage manufacturers follow rigorous equipment cleaning and sanitizing regimens, striving to remove any trace of contamination. Steam and other treatments are hard on process equipment though and that’s why food industry standards require the use of 300-grade stainless steel.

The CDC estimates that each year 48 million Americans eat something that makes them ill. Thus cleanliness is of a paramount concern to the food & beverage industry as any contamination can be very expensive. To prevent this, food and beverage manufacturers follow rigorous equipment cleaning and sanitizing regimens, striving to remove any trace of contamination. Steam and other treatments are hard on process equipment though and that’s why food industry standards require the use of 300-grade stainless steel.

Stainless delivers both temperature and corrosion resistance and can be polished to a very smooth finish, helping ensure the safety of the food and supply.

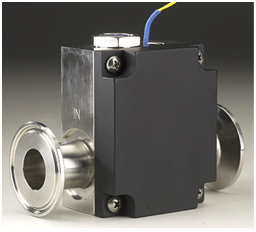

ChemTec’s 500 BP Flow Monitor

ChemTec has developed the Ultra- High Purity 500 BP flow monitor to deliver the in-service performance demanded by the food and beverage industry (as well as many other industries). Eliminating threaded ports eliminates one significant source of contamination while electro-polished interior surfaces are easier to clean and improve fluid flow.

500 ByPass Series – “Adjustable Flow Monitor”

- Low Minimum Operating Pressure

- Close ON-OFF Differential

- Ease of Adjustability

- In Line 180 Degree Porting

- Monitors Gases or Liquids

- Confirms Normal Flow Conditions

- Senses: High Flow or Low Flow Conditions

- Water or Explosion Proof Covers

Materials:

- 316SS

- Brass

- Teflon®

Output:

- Switch Contact

Downloads:

Call our expert Ryan Herco sales staff today at 800-848-1141 to find out how ChemTec products can help assure the high purity integrity of your system.