Custom Chemical Processing Systems

With over 65 years in the industry, Ryan Herco Flow Solutions designs and builds high quality, custom systems for chemical feed, pH neutralization and water and wastewater treatment applications. In addition, our well known line of Herco-Lift pump stations can be found throughout the industry. Our systems are designed and built from the ground up to specifically match the needs of your process. Our highly trained engineers will work with you to evaluate your application parameters and design a system with the right components to reliably and safely handle the toughest requirements.

With over 65 years in the industry, Ryan Herco Flow Solutions designs and builds high quality, custom systems for chemical feed, pH neutralization and water and wastewater treatment applications. In addition, our well known line of Herco-Lift pump stations can be found throughout the industry. Our systems are designed and built from the ground up to specifically match the needs of your process. Our highly trained engineers will work with you to evaluate your application parameters and design a system with the right components to reliably and safely handle the toughest requirements.

Our expertise falls into three broad categories – pH Neutralization, Chemical Blending systems, and Water and Wastewater Treatment. Each of these uses components from world-class manufacturers that you know and trust. Not looking for one of these systems? No Problem! Our engineers have designed countless custom systems and will work with you to specify the right system for your needs no matter its nature or complexity. We will provide detailed drawings for your approval prior to the start of manufacturing.

pH Neutralization Systems

Batch Neutralization RHFS batch pH neutralization systems collect your intermittent flows of waste water and store it for a period of time while quickly and efficiently bringing the pH value to within the proper range by the controlled addition of either acid or caustic. You can rest assured that upon discharge into the sewer your effluent will be in the range you select.

Continuous Neutralization RHFS continuous pH neutralization systems begin with a large reservoir of neutral liquid. The system continuously monitors the pH value of the treatment tank as your wastewater is added, maintaining the pH level within the target range through the addition of acid or caustic. The effluent that flows out of the drain will be within the desired range and can be safely routed into the sewer.

Continuous Neutralization RHFS continuous pH neutralization systems begin with a large reservoir of neutral liquid. The system continuously monitors the pH value of the treatment tank as your wastewater is added, maintaining the pH level within the target range through the addition of acid or caustic. The effluent that flows out of the drain will be within the desired range and can be safely routed into the sewer.

Features:

- Easy installation: skid mount systems can be installed with a forklift and panel mount configurations are available when floor space is tight. Make one electrical connection and plumb to the inlet and outlet to get started!

- Variable input: wastewater pH can vary over time as the system stores and equalizes before treatment.

- Flexibility: systems can handle intermittently generated wastewater since it stores it before neutralizing.

- Interchangeability: storage tanks, mixers and transfer pumps already in place can easily be incorporated into the system.

- Options: data-logging, alarms, and compliance confirmation can be incorporated into the system.

Chemical Blending Systems

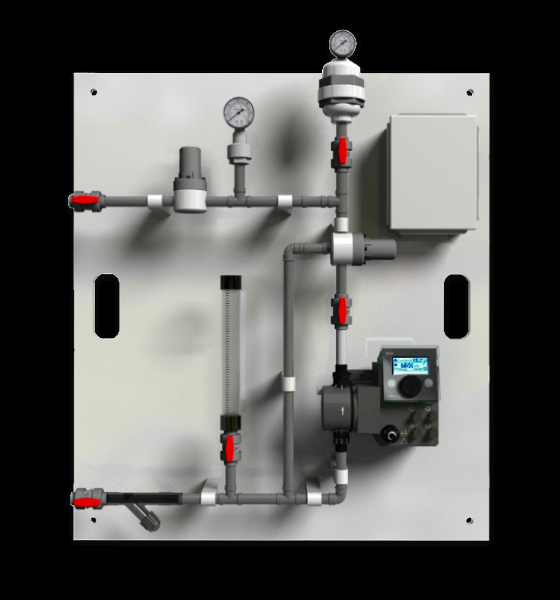

Our chemical blending systems are designed to provide you with a complete solution for your chemical addition or dilution applications. By combining a dosing pump with fluid measurement instrumentation, we can blend chemicals such as inhibitors, dispersants, oxidants and many others at the proper rate. The dosing pump is typically paced by an external signal generated by the instrument measuring the controlled parameter.

Our chemical blending systems are designed to provide you with a complete solution for your chemical addition or dilution applications. By combining a dosing pump with fluid measurement instrumentation, we can blend chemicals such as inhibitors, dispersants, oxidants and many others at the proper rate. The dosing pump is typically paced by an external signal generated by the instrument measuring the controlled parameter.

Our turnkey systems can be designed as wall mount, skid mount and with or without enclosures. We carefully build each system to meet your application’s exacting standards, and use the highest quality components from the world-class manufacturers you know and trust.

Features:

- Wide performance range: systems can be designed with injection rates from 10 ml/hr up to 1,000 gph and injection pressures up to 2,900 psi.

- Compact footprint: simple four bolt attachment for wall mount units or compact skid mount systems free your valuable floor space.

- Easy to install and operate: just put in place, connect the electrical and plumb to the inlet and outlet to get started.

- Designed for corrosive environments: all components are thermoplastic and pump enclosures are NEMA 4X to withstand the harshest environments.

- Dual containment piping and spill containment are available options.

Typical applications can include:

- Industrial: pH adjustment, cooling tower water, boiler water treatment, process chemical addition.

- Municipal Wastewater: disinfection management, pH adjustment, odor control, treatment chemical addition.

- Municipal Water: disinfection management with sodium hypochlorite, fluoride or polymer systems, odor control, iron removal.

- Food & Beverage: vitamin & nutrient injection, clean-in-place (CIP), sterilizer water treatment, cleaning chemical (such as peracetic acid) addition.

Water & Wastewater Treatment Systems

Ryan Herco can work with you to design a water or wastewater treatment system that perfectly suits your needs. We specialize in water & wastewater treatment systems that are self-contained and can simply be integrated into an overall treatment protocol.

Beginning with the measurement of a wastewater parameter such as flow, pH/ORP, turbidity, chlorine residual or conductivity, the parameters are converted to control signals that automatically operate one or more chemical dosing pumps, filters or control valves. Both physical and chemical methods can be used to bring wastewater into compliance. These methods include solids & particulate filtration, particulate flocculation with gravity separation, floatation, pH adjustment, and disinfection. RHFS has access to all of the proper components to precisely configure your system and to do so at a competitive price and within a timeframe that won’t put you behind schedule. We can even build the system on your site if the requirements dictate!

Beginning with the measurement of a wastewater parameter such as flow, pH/ORP, turbidity, chlorine residual or conductivity, the parameters are converted to control signals that automatically operate one or more chemical dosing pumps, filters or control valves. Both physical and chemical methods can be used to bring wastewater into compliance. These methods include solids & particulate filtration, particulate flocculation with gravity separation, floatation, pH adjustment, and disinfection. RHFS has access to all of the proper components to precisely configure your system and to do so at a competitive price and within a timeframe that won’t put you behind schedule. We can even build the system on your site if the requirements dictate!

Herco-Lift Pump Stations

Herco-Lift pump lift stations come in a variety of sizes and configurations so suit your application requirements. Featuring vertical centrifugal or air-operated double-diaphragm (AODD) pumps, with a single pump or duplex pumping configuration, and with or without double-containment, our highly trained engineers and customer service reps will work with you to select the appropriate standard configuration or design and build a custom system that will handle your needs and save you time and money.

Features:

Features:

- Designed for ease of maintenance and repair

- Fully assembled – just plumb and power!

- Wide range of storage, flow and head capabilities to meet your requirements

- Rugged, corrosion resistant tank construction with 1/2" thick polypropylene cover

- Small footprint

- Ideally suited for under sink or behind tool installation

- Clear PVC inspection windows

- Reliable and trouble free Flowline level control